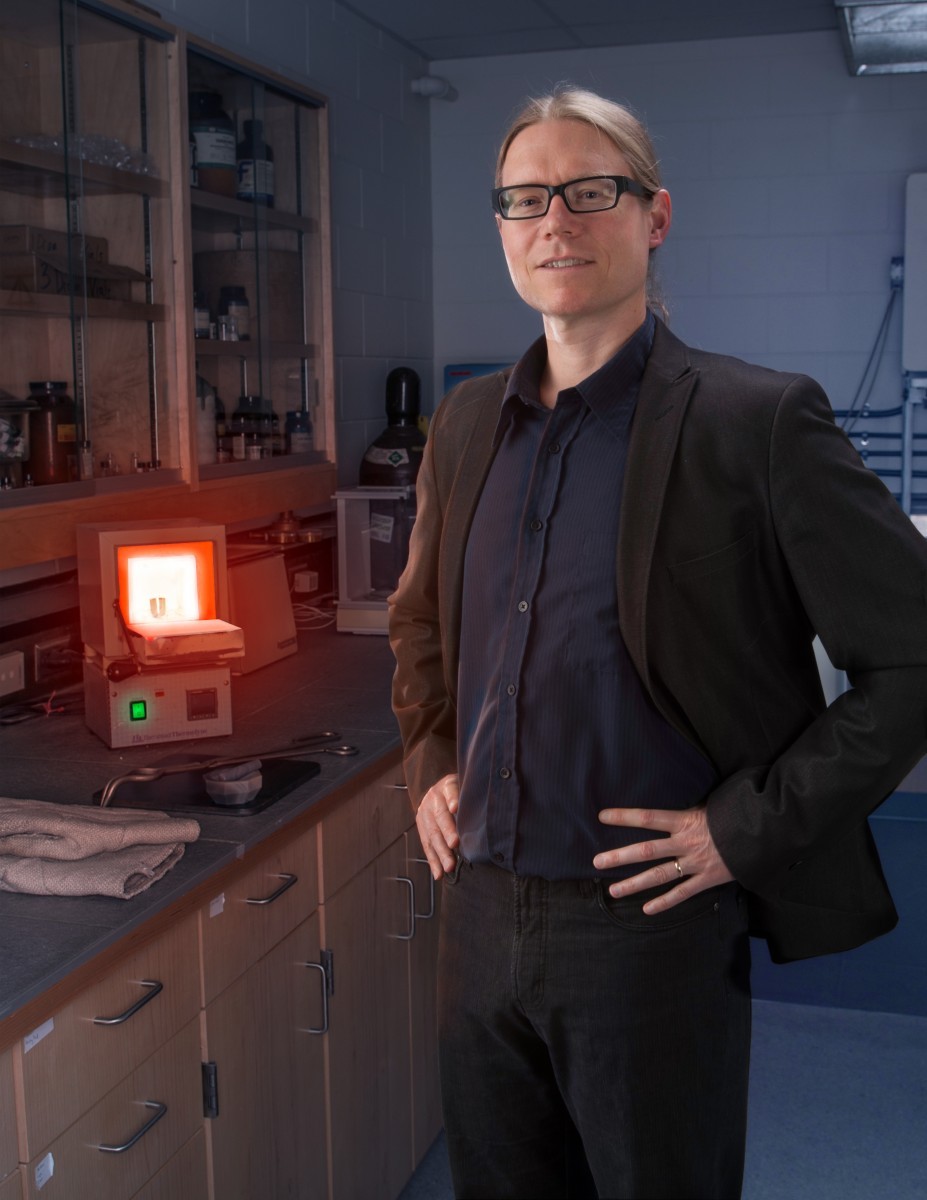

Scott Kroeker

Glass action: understanding the properties of glasses

Most people associate magnets and their properties with physics, but on the fourth floor of the Parker Building in the Faculty of Science, it’s all about how magnets can be used in chemical research.

Chemistry professor Scott Kroeker’s research on the structure of glasses uses huge superconducting magnets to understand these unique materials.

“Nuclear magnetic resonance is at the heart of all my research.”

Kroeker explains that most solids are conceptualized as crystalline. A simple example is sodium chloride— ordinary table salt—where it’s easy to see that it’s made of tiny crystals.

Glass is formed when certain materials are melted at a high temperature then rapidly cooled, preventing crystallization. Instead, the material “freezes” into a disordered solid state with very different properties.

The most common glass in use today is soda-lime glass, made of mostly silicon dioxide (SiO2), sodium oxide (Na2O) and lime (CaO). When cooled from the melt phase, it produces the window glass that we have in all our offices and homes.

Materials considered glasses do not have crystalline order and are difficult to study on a molecular scale because their local structure varies subtly in different parts of the glass.

Nuclear magnetic resonance spectroscopy (NMR)

In fact, X-ray diffraction can’t resolve the structure of glasses, but a completely different process known as nuclear magnetic resonance spectroscopy (NMR) can be used to probe their molecular structure by looking at the various frequencies within the material.

Kroeker’s lab contains three NMR spectrometers. Unlike the magnetic resonance imaging (MRI) systems found in many hospitals, the magnets in Kroeker’s lab stand vertically.

In MRI systems, the magnets are oriented on their sides with a large hole into which patients pass for internal analysis. MRI uses radio frequency fields to map the local environments of the hydrogen nuclei of water in different parts of a body, providing images representing the internal structure of the tissue.

The NMR instruments used to study the structure of glasses don’t use magnetic field gradients to produce an image, but instead use homogeneous fields to measure absorbed electro-magnetic radiation at frequencies that depend on the isotopes under observation. The structural information comes from the chemical shift of a nucleus, the characteristic frequency with which the atom resonates and which can be measured with great accuracy. The NMR spectrometer detects such frequencies and can determine the local molecular structure of materials by comparing frequencies of known elements.

Although much of his research involves glassy materials, Kroeker considers himself principally an NMR spectroscopist.

“What I do is very specialized. Without an effective and efficient NMR spectrometer, much of this research would be impossible, and I’d have nothing to do!” he laughs.

Fibre Optics

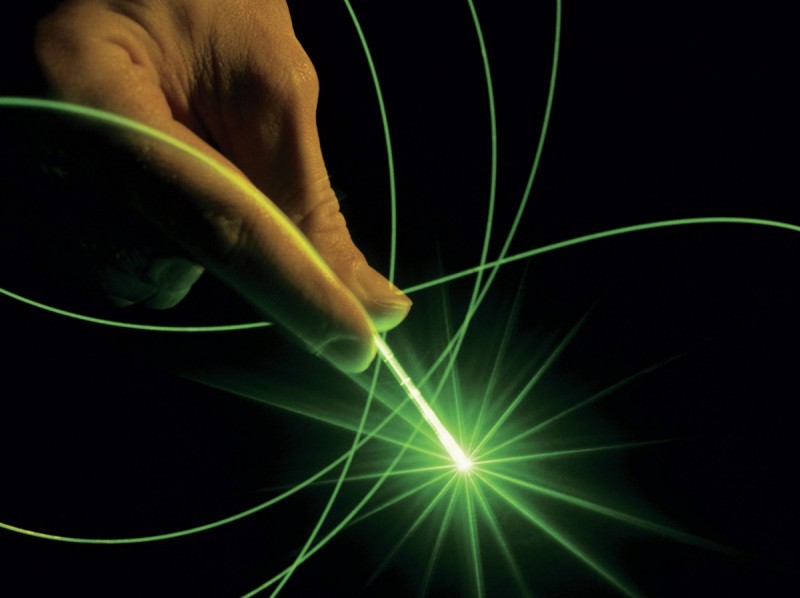

Part of Kroeker’s research on glasses is concentrated on fibre optics, the thin transparent wiry material that is widely used in in- formation technology. Optical fibres are much more efficient than copper wire for transmitting information, but even they have their limits. Whereas copper wire needs periodic repeaters to boost electrical signals in order to transmit long distances, light travelling through optical fibres doesn’t need as many repeaters, but it does need some for long-distance transmission. The distance the light can travel before regeneration depends on the purity of the glass fibres.

Fibre optic repeaters are usually inline lasers in which photons are reflected back and forth until they burst out of the cavity as a new laser pulse. These lasers are typically spaced about 100 kilometres apart, so that very long distances can be covered at the speed of light.

Kroeker uses NMR spectroscopy to study how the optical properties of new laser glasses are influenced by the composition and structure of the glass. More effective laser materials will improve long-distance data transmission.

A second aspect of Kroeker’s research looks at exactly the reverse: studying how to add impurities into melted materials as they cool so that they don’t crystallize but instead form glass. This is important in a number of processes, but none so critical as in the long-term storage of nuclear waste.

Kroeker explains that most countries reprocess radioactive waste from the spent fuel rods used in nuclear power. Canada stores its nuclear waste underground rather than reprocessing.

In countries where nuclear waste is reprocessed, such as France, the procedure generates waste products in liquid form.

“It’s necessary to deal with this nuclear waste properly because it can remain dangerous to humans for up to a million years.”

The best way to contain such liquid nuclear waste is to immobilize it in glass. Typically, the waste is mixed in with liquid borosilicate glass at a temperature of about 1100°C. This temperature is hot enough that the nuclear waste products dissolve within the liquid glass and then harden into a more compact and durable material.

However, there are some radioactive elements that don’t dissolve well in the liquid glass. Instead, they create crystalline regions within the glass that can, unfortunately, dissolve in water. Obviously, this would be a problem if the hardened glass came in contact with water while in storage. Kroeker’s research involving nuclear waste is determining the nature of the crystalline regions within glass.

“X-ray diffraction can’t do it,” he says. “The only way to probe the resulting complex glass-crystalline composites is NMR spectroscopy.”

To study how the crystalline deposits form inside the glass, Kroeker uses the cesium-133 isotope, which is not radioactive but reacts chemically exactly like its radioactive cousins, cesium-137 and cesium-135, found in nuclear waste. He does NMR of the solid glasses at room temperature and of the melted glass using laser heated equipment, so he can mimic the industrial formation of these materials.

“We are trying to understand the chemistry of partly crystallized glass to improve its durability. My research focus is to determine the chemical composition of the crystalline phases and ultimately, to eliminate crystallization so that all the dangerous constituents are securely locked up in the glass.”

He adds: “While it seems complicated, our hope is that the work we are doing here in Manitoba will create a safer world for generations to come.”

The main funding for Kroeker’s work is through grants from the Natural Sciences and Engineering Research Council of Canada (NSERC) and Canada Foundation of Innovation (CFI). Additional funding has facilitated his travel and research visits to the UK and France to work with their nuclear waste organizations.

by Chris Rutkowski

originally published in ResearchLife, Summer 2014

Can we grow chrisaline shapes in those shapes?