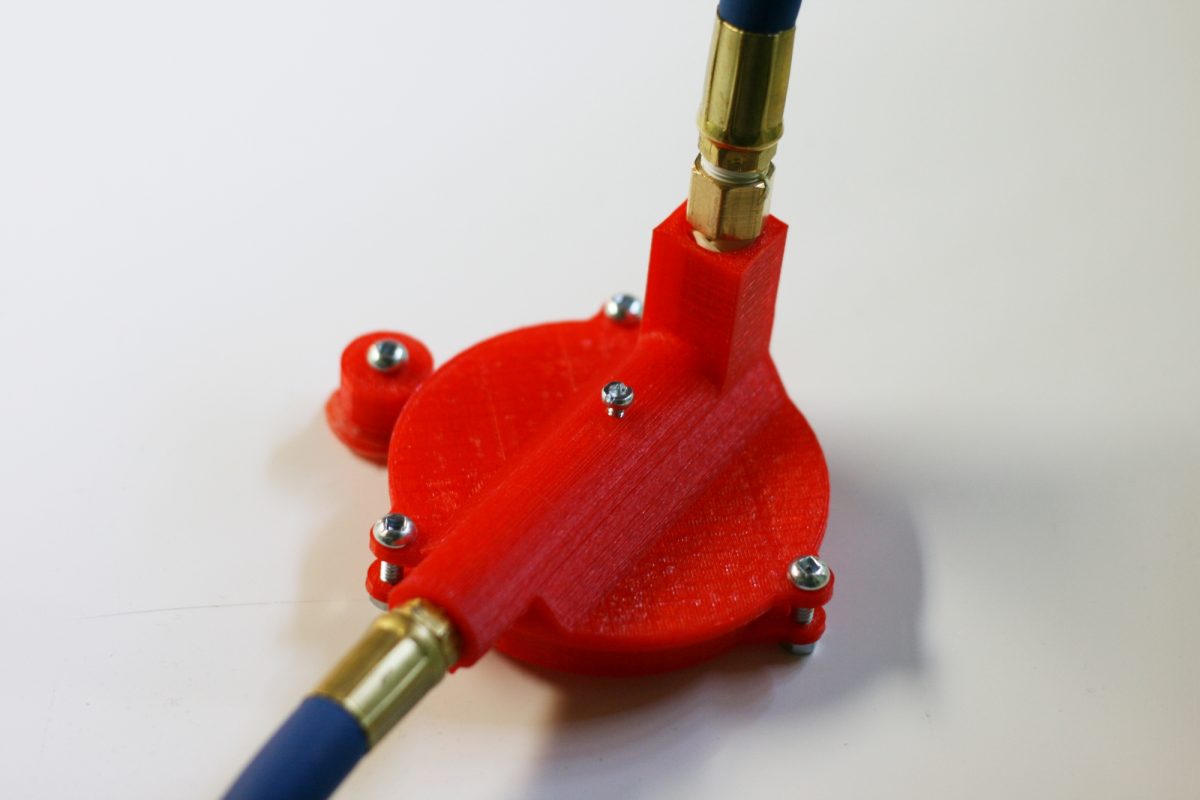

This 3D-printed ventilator, developed by a group of University of Manitoba professors, costs less than $20 to produce.

UM team develop inexpensive 3D-printed ventilator following shortage

Doctors around the world could turn to a made-in-Manitoba design if hospitals experience a ventilator shortage during the second wave of COVID-19.

A group of University of Manitoba professors have developed an inexpensive 3D-printed ventilator that could be used in an emergency. The goal is to have the plans available online so that anyone could produce the ventilators.

Dr. Sean O’Brien, an instructor of mechanical engineering, Price Faculty of Engineering, got the idea to develop a 3D-printed ventilator after hearing that hospitals in Italy had experienced a shortage of the lifesaving machines at the beginning of the pandemic.

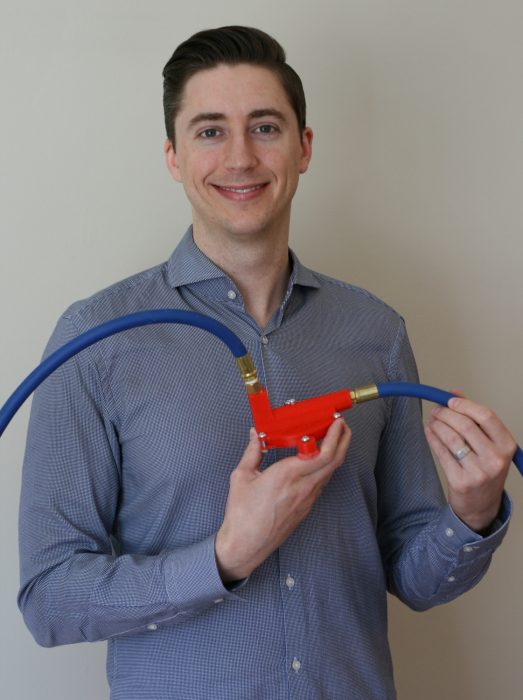

Dr. Sean O’Brien, an instructor of mechanical engineering, Price Faculty of Engineering, holds a 3D-printed ventilator.

“I wanted to try to develop a device that would be fast to produce and very economical so that any country that found themselves running out of ventilators would be able to make some,” he said.

So O’Brien sought the medical expertise of Dr. Lawrence Gillman, associate professor of surgery, Max Rady College of Medicine, Rady Faculty of Health Sciences, and Dr. Faisal Siddiqui, assistant professor of anesthesiology, perioperative and pain medicine, Max Rady College of Medicine.

“Ventilators are normally super complicated, and have computer systems and monitors,” Gillman said. “This is a bare bones, basic ventilator that you could throw together in a pandemic if you needed something in a pinch.”

While ventilators used in hospitals can cost more than $25,000, the team’s 3D-printed machine is less than $20 to produce. O’Brien is also working on developing a ventilator with a monitor that would cost under $100.

All that’s needed to manufacture the ventilator is a 3D printer, which takes about two hours to print each device. Alternatively, the ventilators could be vacuum formed in about 10 minutes per unit using a 3D-printed mould, a vacuum cleaner, a basic kitchen oven and widely available sheets of plastic.

The team developed the ventilator in just two weeks so they could enter it into the Code Life Ventilator Challenge run by the Montreal General Hospital Foundation and the Research Institute of the McGill University Health Centre.

O’Brien said the ventilator has done well on preliminary tests but requires refinement. He is planning to get his students to work on further developing the ventilator as part of a course project this fall.

“I’m excited to see what ideas the students will come up with,” he said.

The team will make the plans available online once the design is fully developed.

“We hope our ventilator will be beneficial, not only as an emergency pandemic ventilator but also as a critical ventilator in countries with fewer resources,” O’Brien said.