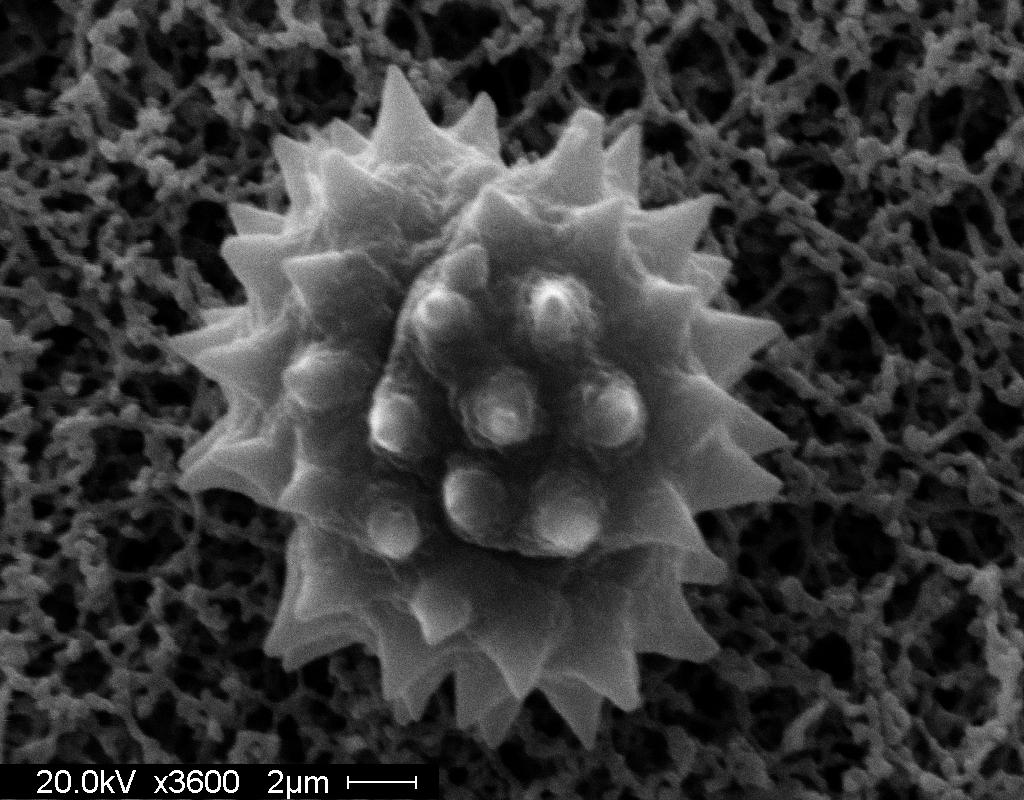

An image of pollen, magnified 3,600x, from the perennial wildflower balsam ragwort (Senecio pauperculus, Asteraceae). A graduate student working with MIM used pollen grain images such as this to construct a “pollen library” of co-flowering species associated with the endangered small white lady’s slipper orchid (Cypripedium candidum).

Manitoba Institute for Materials transforms into global leader

New facility will ensure Manitoba’s lead position in aerospace and composite materials research

With a federal investment of $3,500,000 announced on June 24, the University of Manitoba will purchase three different high-performance electron scanning microscopes and establish an advanced materials characterization facility in the Manitoba Institute for Materials (MIM).

The equipment is so cutting-edge, the University of Manitoba was the first institute in the world to order it.

This state-of-the-art facility, made possible by Western Economic Diversification, a federal program, will enable academia and industry to integrate more fully and capitalize on the growing emphasis on composites and aerospace research and development being undertaken in Western Canada.

“Investing in the Manitoba Institute for Materials will strengthen our University’s and our province’s position at the national forefront of material-related research and development,” said Dr. David Barnard, President and Vice-Chancellor of the University of Manitoba. “This promising new laboratory will empower our researchers to make discoveries that impact lives here and around the world.”

The recently-appointed Director of MIM, Derek Oliver, paid tribute to the founding vision for the facility.

“Michael Freund, our outgoing Director, and Digvir Jayas, Vice-President (Research and International), have worked tremendously hard to bring this exciting project to fruition. The new facility will not only boost the productivity of world-class scientists and strengthen partnerships with industry, but it can be quickly re-configured as a teaching and training space. Hands-on access to these instruments will become a part of the undergraduate and graduate student experience in addition to a key aspect of courses offered to industry.”

The equipment will be housed in a new facility accessed by an above ground structure on what is currently parking Lot A, with the labs located below ground in space that currently stores a decommissioned cyclotron. The space is being re-developed for MIM.

MIM facilitates and enhances basic and applied materials science in the prairie region. It brings together local industry and academia with international companies like GE, who are contributing $300,000.

This new facility will ensure Manitoba’s lead position in aerospace and composite materials research.

This new facility will ensure Manitoba’s lead position in aerospace and composite materials research.

The new infrastructure will include high-performance and easily accessible electron microscopes that will provide industry, researchers, and students an integrated world-class research and training facility.

The high-resolution electron microscopes will be capable of studying complex structures and offer X-ray techniques for understanding the role of interfaces and bulk properties on material performance. These capabilities will align with Composites Innovation Centre (CIC) and regional industry through fundamental material assessment and characterization; they will support manufacturing and prototype-scale testing as well as the investigation of new material issues.

MIM currently possesses a range of tools and technical expertise that, when bolstered by the new tools, will provide a world-class facility to support the growing composites and aerospace materials research effort in the Prairie region as well as the broader R&D community.

FEI, a world leader in the development of electron microscopy techniques, recognizes the incredible potential in establishing a world-class facility in Manitoba and will contribute $2 million toward the new equipment. Western Economic Diversification will provide $3.5 million toward the new equipment.

All together, the facility will represent one of the most modern and complete materials characterization facilities in North America openly available to both academia and industry. Construction will be completed in the first half of 2015.

Error thrown

Object of class WP_Error could not be converted to string